Viscose – also known as rayon or artificial silk – is one of the most popular materials in the fashion industry. It’s a fibre that is man-made from trees that became popular as a cheaper and more durable alternative to silk. It’s often used to create drapey summer dresses, skirts, soft blouses, and synthetic velvet. But viscose isn’t just found in our clothes — it’s also used in the manufacturing of upholstery, bedding, and carpets.

Viscose rayon was invented in France but was so flammable it was quickly taken off the market. In 1892, two British scientists discovered and patented a safe and commercially viable production process, and by 1905 the first viscose rayon was on the market.

Viscose is derived from the cellulose (or, wood pulp) from fast growing, regenerative trees such as eucalyptus, beech, and pine. This cellulose material is dissolved in a chemical solution to produce a pulpy viscous substance, which is then spun into fibres that can then be made into threads.

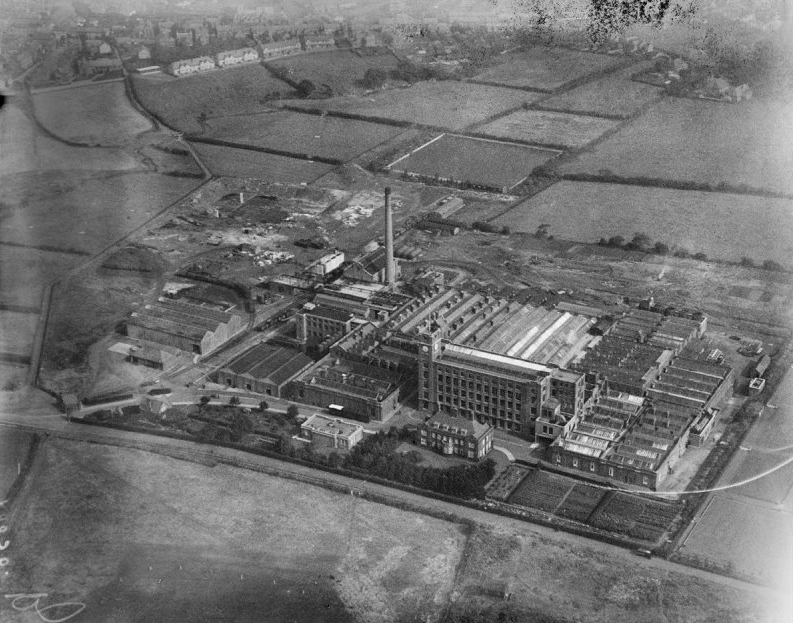

In 1904 Courtaulds Ltd. acquired the patents and set up the first factory to produce it in Coventry. The process remained troublesome until further inventions improved yarn strength. However, in a few years the process became highly successful and was responsible for transforming the company into the world’s leading man-made fibre production company.

Production in North Wales

North Wales was once at the heart of the rayon industry in the UK. It began when the British Glanzstoff Manufacturing Company, a subsidiary of a German company, started an artificial silk factory in Flint in 1907. This was taken over by Courtaulds in 1917, who then bought the old Muspratt Alkali factory and Holywell Textile Mill in Flint in the 1920s, calling them the Castle Works and Deeside Mill respectively. After conversion they started production of manufactured viscose rayon yarn.

At its height Courtaulds employed over 10,000 people at four sites. At Greenfield, some 5 miles further down the Dee estuary, two additional large rayon production facilities existed from 1936 onwards, named Number 1 and Number 2. These mills employed over 3,000 people.

Textile production declined from 1950, and Aber works shut initially in 1957, opened for rayon in 1966, and pulled down in 1984. Castle works closed in 1977 and Deeside Mill in 1989. The number 1 facility at Greenfield was mothballed in 1978, and the entire site was decommissioned in the mid 1980s.